BLOG

1.Why does the battery need to be balanced?

The main reason is that there is always some difference between the cells in a battery pack, such as voltage, internal resistance, charging and discharging characteristics, etc. Just as there are no two identical leaves in the world, we cannot find two identical battery cells. Though the difference may seem to be trivial at first, from a long term perspective, it will cause inefficiency and over-degradation in the battery. Therefore it needs to be improved through balancing.By now, there are two main balancing technologies in battery industry.

2. Passive Balancing

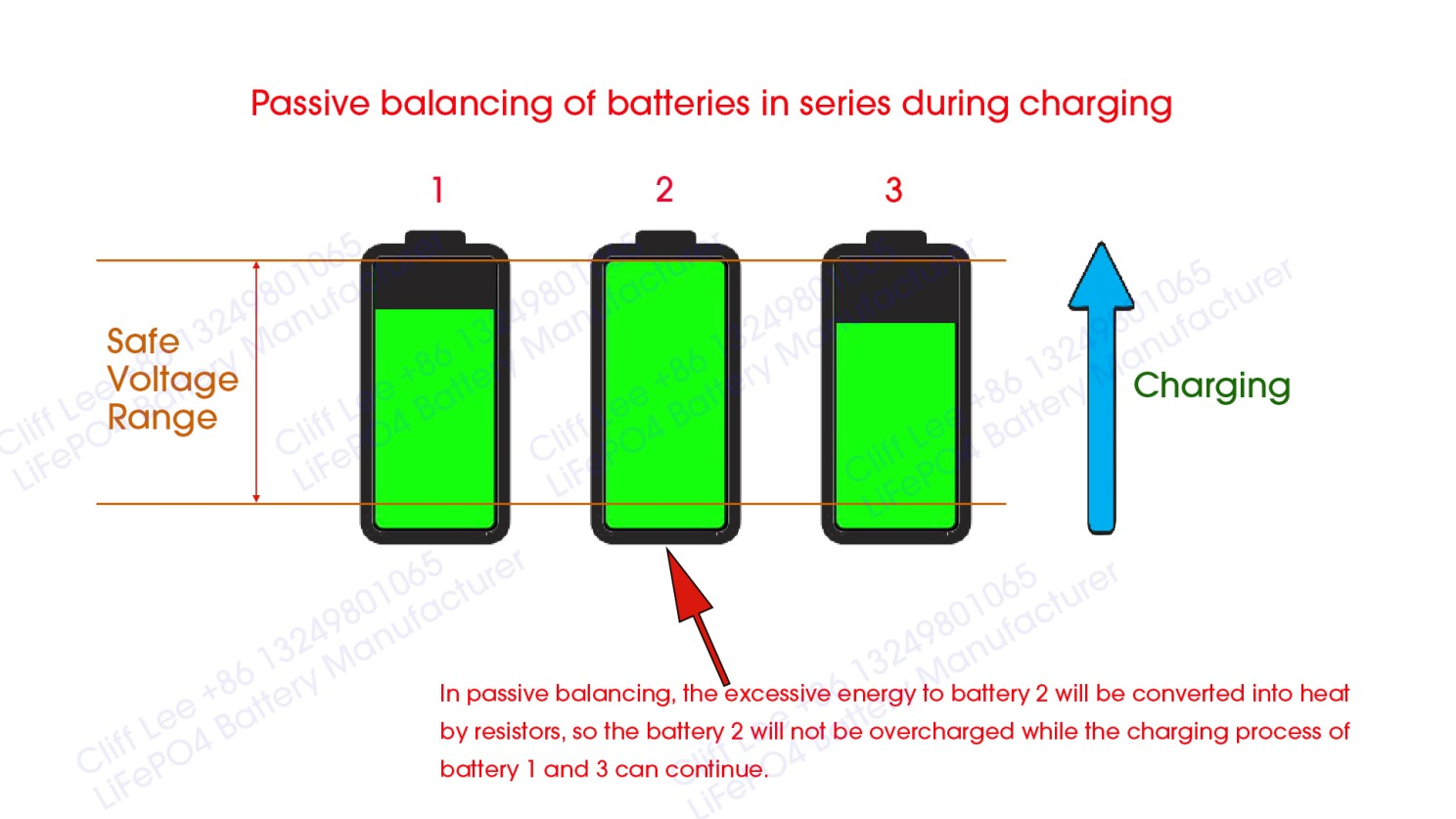

Suppose there are three battery cells connected in series to make a complete battery pack. During the charging process, lithium batteries generally have an over charge protection voltage. When a certain string of battery cells reaches this protection voltage, the lithium battery BMS will cut off the charging circuit and stop charging. Therefore the No. 1 and No. 3 batteries cannot be fully charged. The actually charged energy capacity of the entire system is limited by the No. 2 battery.

Passive balancing generally discharges the battery cell with higher voltage through resistor consumption, releases the power in the form of heat, and buys more charging time for other battery cells to be fully charged.

Picture 1. Passive Balancing - Charging Process

As shown in Picture 1, after the passive balancing is started, the lithium battery BMS will discharge the No. 2 battery and delay the time when it reaches the protection voltage value, so that the charging time of the No. 1 and No. 3 batteries will also be extended accordingly, thereby improving the entire battery capacity. However, 100% of the discharged power of the No. 2 battery is converted into heat and released, causing energy waste.

The advantages of passive balancing are low cost and simple circuit design. It has been widely used in energy storage batteries which usually adopts a lower C-rate charging and discharging process.

Picture 2. Passive Balancing - Discharging Process

The disadvantage of passive balancing is that it can not balance the discharging process of the battery. As shown in Picture 2, during discharging, when the voltage of the No. 2 battery reaches the discharge protection low voltage, the protection mechanism of the lithium battery BMS is triggered, and the system discharge is shut down, which directly causes the remaining battery capacity of the No. 1 and No. 3 batteries to be unable to be fully used.

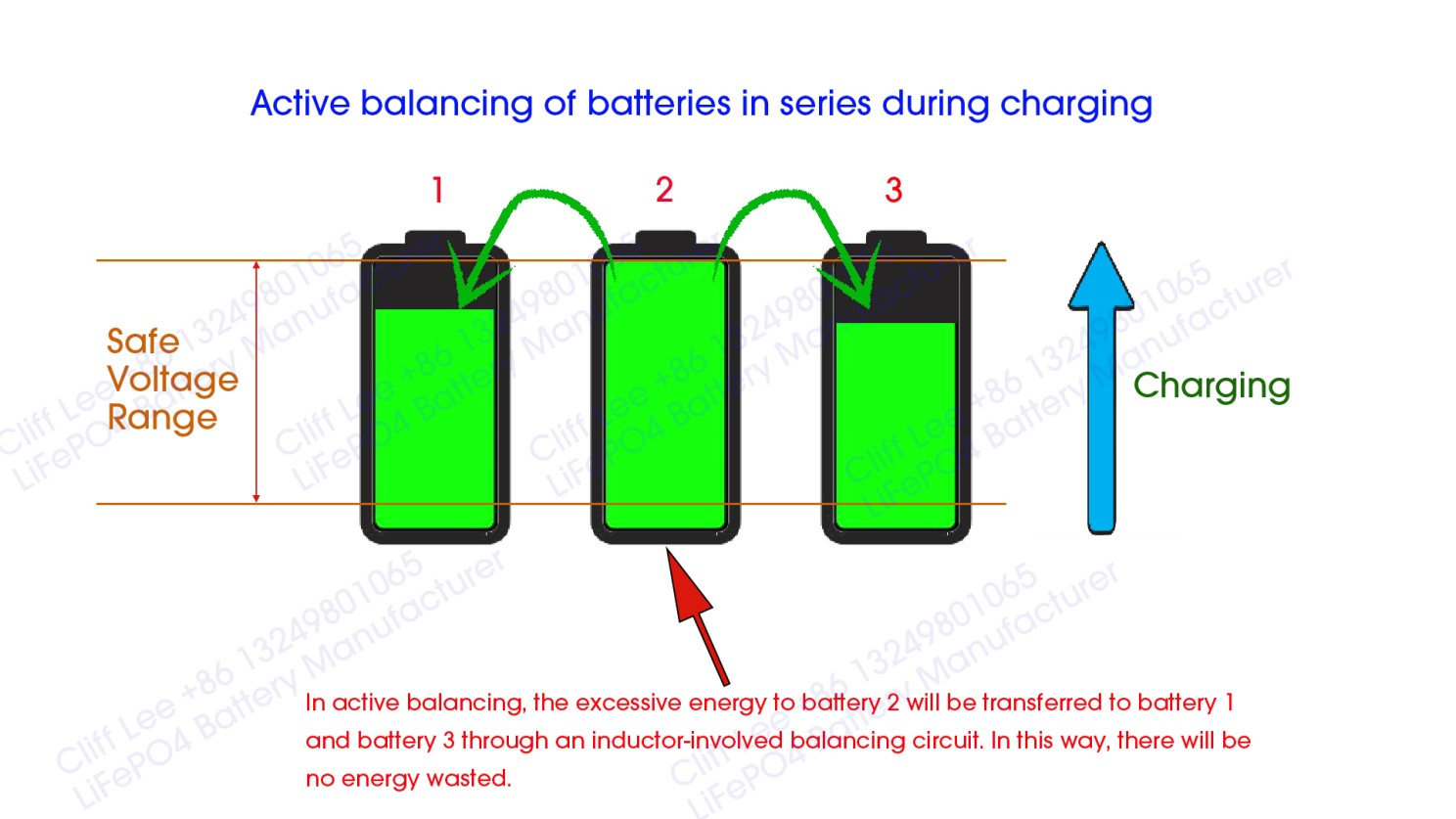

3. Active Balancing

In active balancing, battery cells are balanced by means of power transfer, with high efficiency and low loss. Different manufacturers have different methods, and the equalizing current also ranges from 1 to 10A. Compared with passive balancing, which is suitable for small-capacity, low-series lithium battery pack applications, active balancing is suitable for high-series, large-capacity power lithium battery pack applications.

Inductive active balancing is based on physical conversion, integrates power switches and micro-inductors, adopts a two-way balancing method, and balances batteries through charge transfer between similar or adjacent batteries, and can be used regardless of whether the battery is in a discharging, charging or static state.

Picture 3. Active Balancing - Charging Process

Its discharge and charging works on the same principle, as shown in Picture 3, when the battery is in charging process, the No. 2 battery transfers the energy to the No. 1 and No. 3 batteries. Efficient charge transfer keeps the voltage of the three battery cells in a balanced state during charging, so that all batteries can be fully charged.

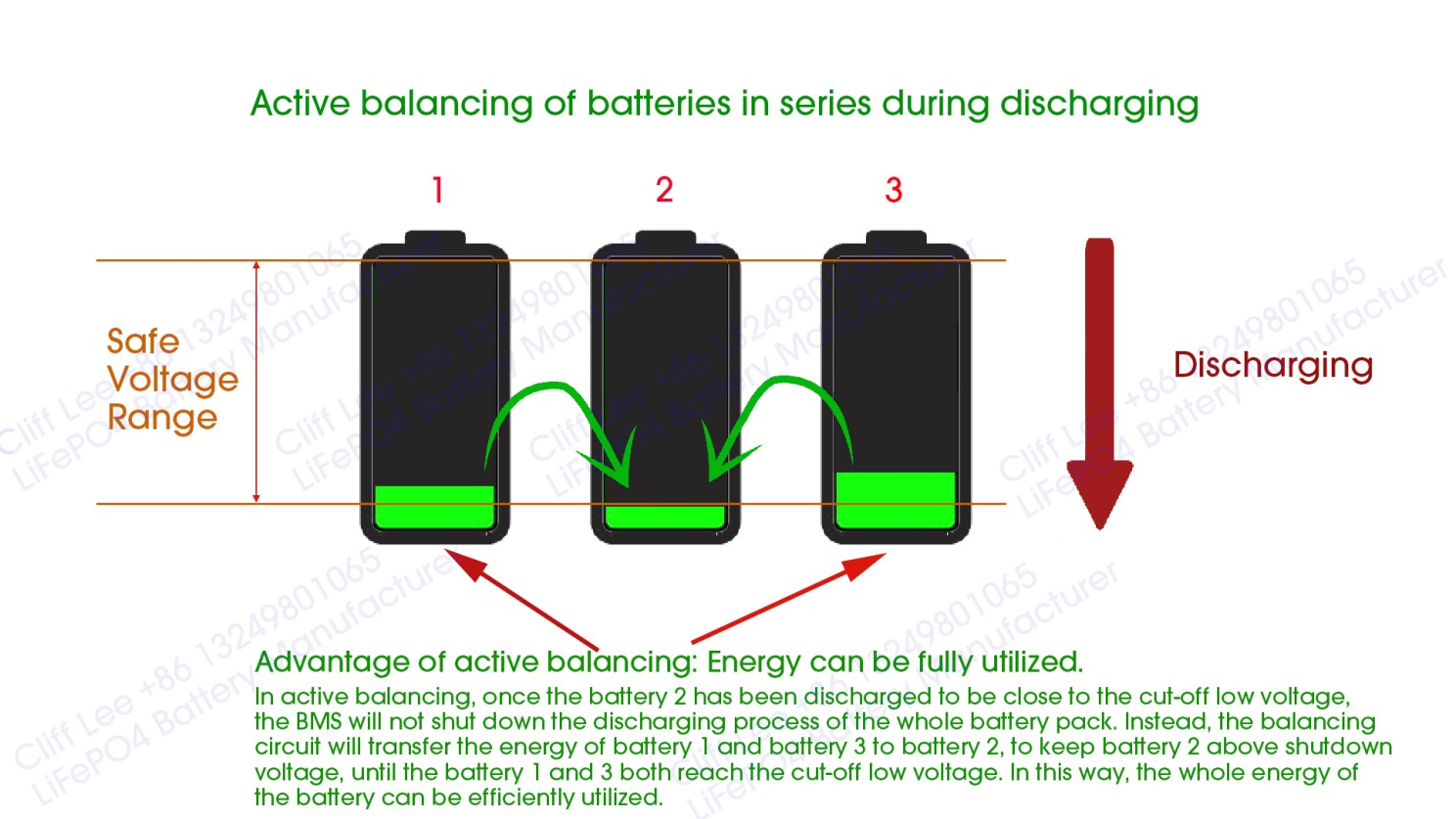

Picture 4. Active Balancing - Discharging Process

When discharging, as shown in Figure 4, No. 1 and No. 3 batteries transfer power to No. 2 battery, and the voltage of the three batteries has been discharged in a balanced state, so that all the batteries’ energy can be efficiently utilized.

The disadvantage of active balancing is the relatively more complicated circuit, so that the price of BMS with active balancing is high. Therefore active balancing technology is mainly used in EV(Electric Vehicle) battery packs.

About quarelex

Established in 2017, Enerri Energy Group(parent company of quarelex), is one of the pioneering companies in applying the lithium-ion battery technology into low-speed motive power batteries and also battery energy storage systems(BESS). Our key solutions include:

1.Lithium-ion(LiFePO4) power batteries for material handling equipment: Forklifts, Narrow Aisle Trucks, Walkie Pallet Jacks, AGVs, etc.

2.Lithium-ion(LiFePO4) power batteries for low-speed vehicles: Golf Carts, E-Bikes, etc.

3.Lithium-ion(LiFePO4) storage batteries for hybrid/off-grid solar system: Residential low&high voltage battery, Commercial battery energy storage systems(BESS).

4.Solar inverters: hybrid, off-grid solar inverters for residential solar systems.

5.Lithium-ion battery charger: 24V-96V, 10A-300A.

6.Cloud-based Energy Management System(EMS).

sales@quarelex.com

+63(0)954-229-7531(PH)

+1(626)715-3359(US)

+86-19899797548(CN)

Building 19, No. 89 Hezuo Road, Chengdu High-tech Zone, Sichuan, China, 610000