BLOG

Cylindrical battery cell: Long development time, most mature technology

Pros: mature technology, low cost, stable and durable, high energy density, high consistency

Cons: small room for increase in energy density, and high requirements for BMS with a large number of cells combination

Cylindrical battery cell

Common 18650 batteries are divided into ternary lithium batteries and lithium iron phosphate batteries. The nominal voltage of the ternary lithium battery is 3.7V, and the charging cut-off voltage is 4.2V. The nominal voltage of lithium iron phosphate battery is 3.2V, the charging cut-off voltage is 3.6V, the available capacity is between 1200mAh-3350mAh, and the common capacity in the market is 2200mAh-2600mAh. This kind of battery is characterized by high capacity, high output voltage, good charge and discharge cycle performance, stable output voltage, high current discharge, stable electrochemical performance, safe use, wide operating temperature range, and environmental friendliness.

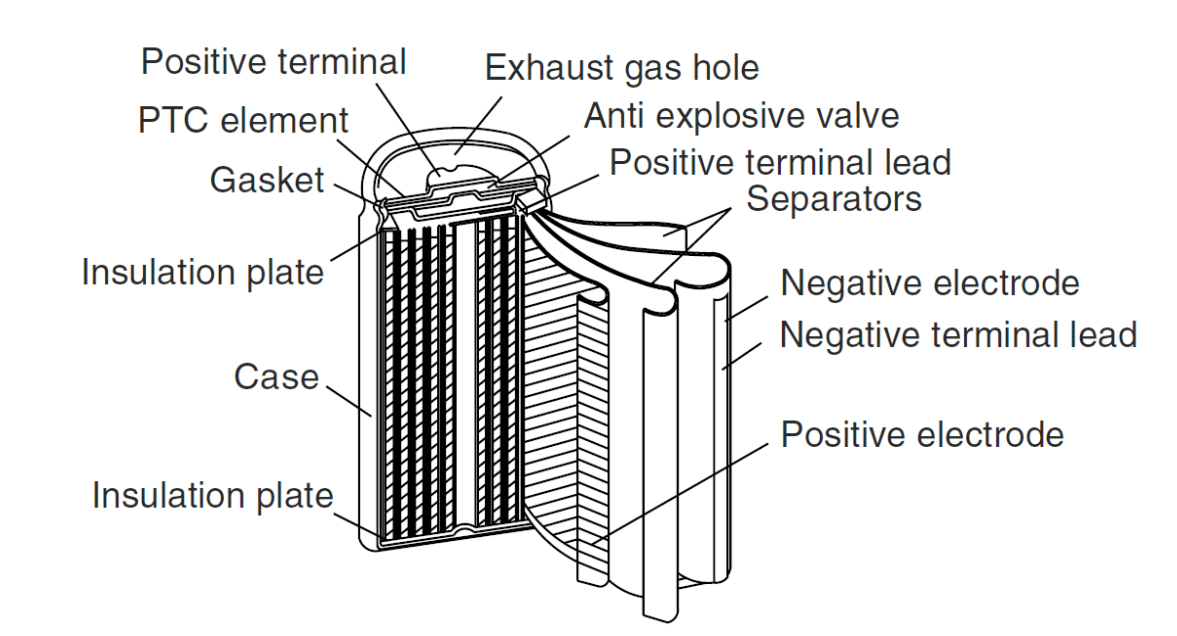

Internal structure of cylindrical lithium battery cell

The earliest cylindrical lithium battery was the 18650 lithium battery invented by Japan's SONY company in 1992. Because the 18650 cylindrical lithium battery has a long history, the market penetration rate is very high. The structure of a typical cylindrical battery includes: positive electrode Cover, safety valve, PTC element, current cut-off mechanism, gasket, positive pole, negative pole, separator, case. Cylindrical lithium batteries adopt a fairly mature winding process, with a high degree of automation, stable product quality, and relatively low cost.

It also has many models, such as the common ones 14650, 17490, 18650, 21700, 26650, etc. Taking 18650 as an example, 18 refers to the cell diameter of 18mm, 65 refers to the height of 65mm, and 0 refers to its cylindrical shape. Others and so on. Widely used in solar lamps, lawn lamps, backup energy, power tools, toy models.

The excessive number of batteries has become a thorny problem faced by electric vehicles. In order to meet the capacity demand, it can only be compensated by a substantial increase in the number. A larger number has higher requirements for the BMS battery management system. Take Tesla's 7,000-unit 18650 as an example. At present, only Tesla's BMS battery management system can meet such a large number of computing requirements. This is one of the reasons why few manufacturers use 18650. In addition, since cylindrical batteries need to use steel shells when they are combined into battery packs, their weight is relatively high. In theory, the energy density of cylindrical batteries after PACK is lower than that of the other two batteries.

After replacing 18650 with 21700, the energy density of the battery increases by nearly 20%, and the cost is significantly lower than that of 18650. The cost of the system is expected to decrease by about 9%, and the weight of the system is expected to decrease by about 10%. So, can't it be possible to build a larger cylindrical battery?

Here you need to know a little knowledge: for every 10% increase in battery capacity, the cycle life of the battery will decrease by 20%, and the cycle life of the battery is related to the voltage of the monomer. According to the latest test, the peak charging voltage of 18650 cells and 21700 cells is 4.2V, while the average prismatic cell is about 3.9V. For every 0.10V reduction in the charging voltage of the battery, its cycle charging life can be doubled. According to the current 18650 and 21700 batteries, its single cycle number is 300-500 times, while the prismatic battery is longer. The charging voltage of the lithium iron phosphate battery is 3.6V-3.8V. The work of the super lithium iron phosphate battery The voltage can reach 3.9V. For all batteries, it is not the appearance that determines its cycle life, but the voltage supported by its body. As the battery capacity increases, the charge and discharge rate will drop by 30%-40%, and the cell temperature will rise by 20%, so this means that a stronger BMS battery management system is needed to effectively control the battery.

Prismatic battery cell: a compromise solution at the moment

Pros: high strength, small internal resistance, long life, high space utilization

Cons: Difficult to unify the production process and difficult to dissipate heat

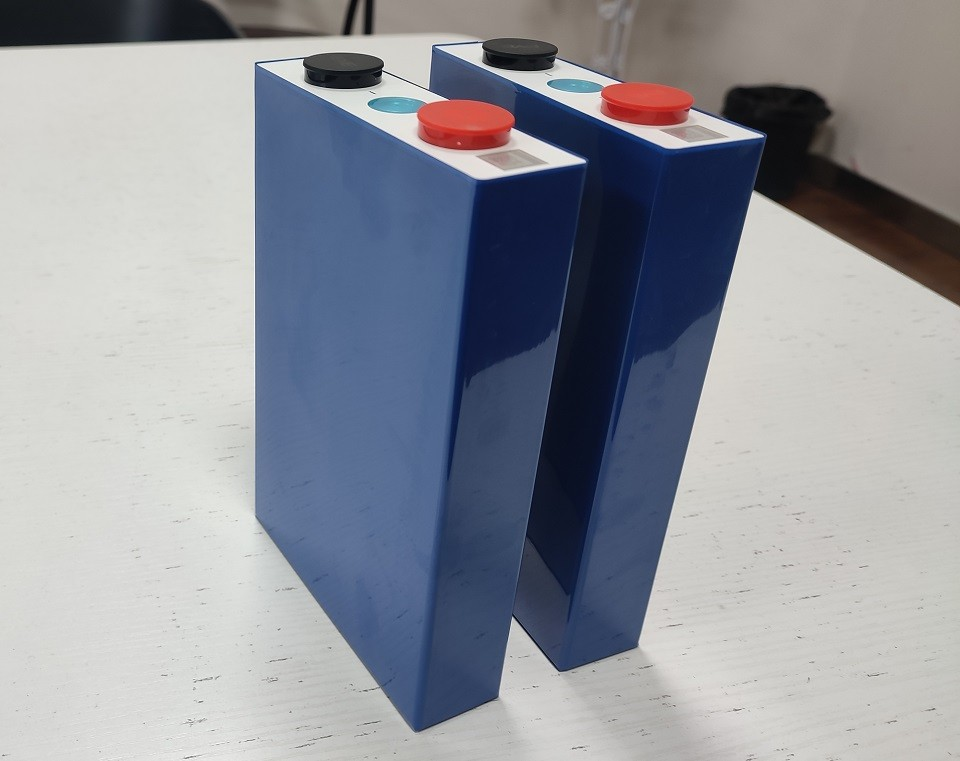

Prismatic battery cell

The prismatic battery is currently the most widely used form of battery pack in the international field. A series of new energy car companies such as Weilai and Geely, which are currently mainstream in China, all use prismatic batteries. One of the main reasons for the wide application of this kind of battery is that it has many suppliers and relatively low technical difficulty. Most domestic battery suppliers choose to develop prismatic batteries. For example, the well-known CATL mainly provides prismatic batteries.

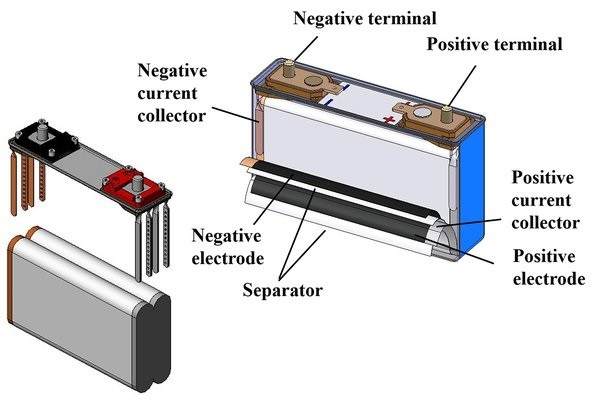

Prismatic battery cell internal structure

Prismatic lithium batteries usually refer to aluminum shell or steel shell prismatic batteries. Domestic power battery manufacturers mostly use aluminum shell prismatic batteries with high battery energy density, because the structure of prismatic batteries is relatively simple, unlike cylindrical batteries that use higher strength. Stainless steel is used as the shell and accessories with explosion-proof safety valves, so the overall weight of accessories is lighter than that of cylindrical batteries, and the energy density of prismatic batteries is theoretically higher than that of cylindrical batteries. It has high structural strength, good ability to withstand mechanical loads, small battery internal resistance, long life, small drop in energy density after composition, and high space utilization.

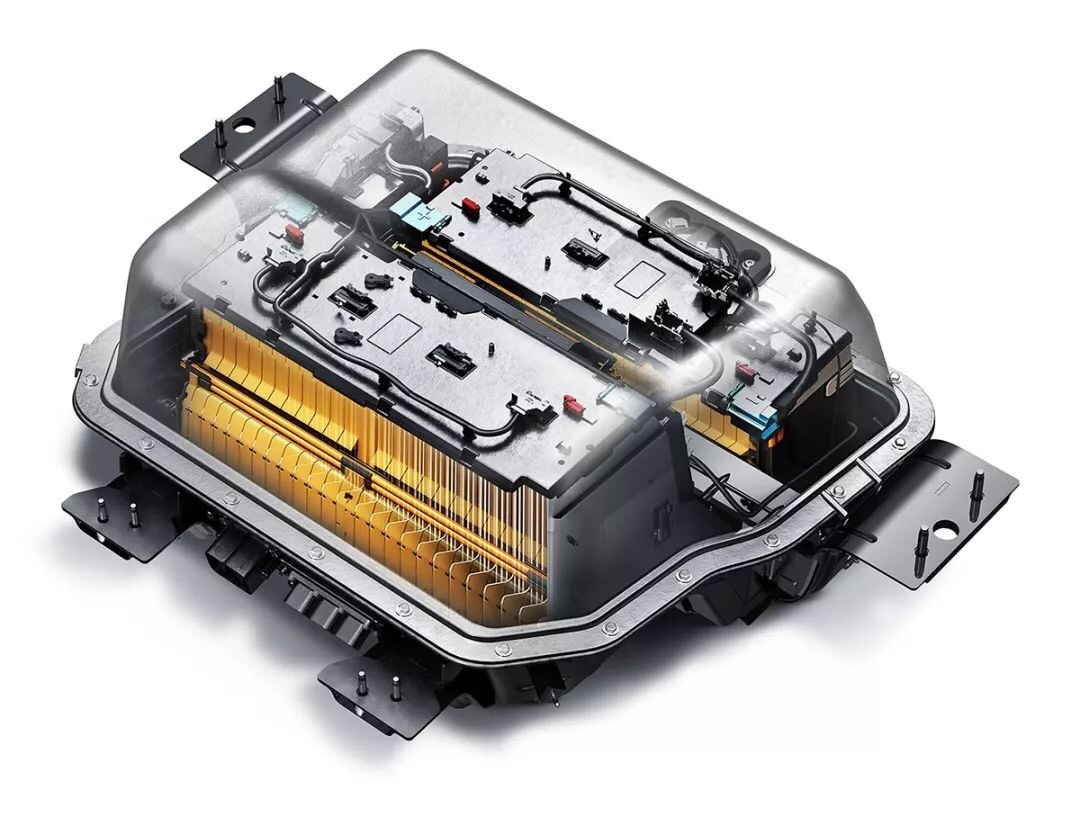

Electric Vehicle battery pack with prismatic cells

There are two different processes for prismatic batteries, winding and stacking. Although the technical difficulty is relatively low, there are still many technically unstable factors that affect the quality of the battery. The cylindrical lithium battery technology is very mature, the common secondary cutting defect probability of the pole piece is low, and the winding process is more mature and automated. The lamination process is still using a semi-manual method. Rectangular batteries are prone to lead ear welding, which affects the quality of the battery, and the chemical activity at the corners is poor, and the performance of the battery will decline significantly after long-term use. The prismatic batteries used in electric vehicles are also different. Because prismatic batteries have to cope with the use of different spaces, they must be customized according to different needs. But behind the high flexibility is the low degree of standardization, it is difficult to achieve a unified process, and it is difficult to dissipate heat.

Pouch battery cell: flexible customization, high process requirements

Pros: High energy density, light weight

Cons: Needs extra protection against battery damage and thermal runaway

Pouch Liuthium Ion battery cells

Although the pouch battery is not widely used in the automotive market, we are no strangers to it. Our mobile phones basically use "pouch batteries", but in 3C digital, we collectively call them pouch batteries, called: polymer batteries. The advantages and disadvantages of pouch batteries are almost hand in hand, because the shape of pouch batteries is flexibly designed (customized according to customer needs, and the battery cells are also remade), so the number of existing pouch batteries of the same model is too small. In addition, the cost of developing a new set of pouch battery packs is also quite high.

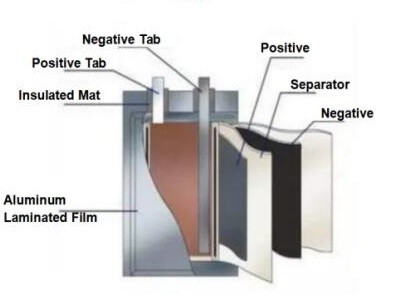

Pouch battery cell structure

Pouch lithium battery is a liquid lithium-ion battery covered with a polymer shell. The biggest difference from other batteries is the soft packaging material (aluminum-plastic composite film), which is also the most critical and technically difficult material in pouch lithium batteries. , which is one of the reasons why domestic battery manufacturers have not promoted pouch batteries on a large scale. Due to the absolute advantages of aluminum-plastic film over steel and aluminum shells in terms of light weight, the weight of pouch batteries is 40% lighter than steel shell batteries of the same capacity, and 20% lighter than aluminum shell batteries. There is an innate advantage in energy. The capacity of the pouch battery is 10-15% higher than that of the steel case battery of the same specification and size, and 5-10% higher than that of the aluminum case battery, which accounts for a great deal of energy density.

The pouch battery adopts a superimposed manufacturing method, which is thinner in volume than the other two types of batteries, so its energy density is theoretically the highest among the three types of batteries. The shape of the pouch battery can be customized according to customer needs. It can be made thinner. The ordinary aluminum case can only be 4mm, and the soft case can be 0.5mm. The flexibility of the battery layout is better than the other two types of batteries.

The shell materials of pouch batteries are different from those of square and cylindrical batteries, which determines their packaging methods are also different. pouch batteries are heat-packaged, while metal-cased batteries are generally sealed by welding (laser welding). If it is really difficult to understand, you can think of the pouch battery as a layer cake.

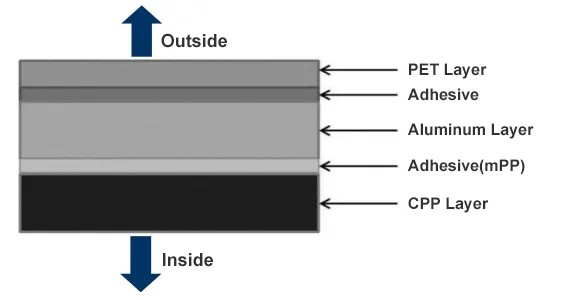

The reason why the pouch battery adopts thermal packaging is that it uses aluminum-plastic packaging film material, which is usually divided into three layers, namely, the outer resistance layer (usually the outer protective layer composed of nylon BOPA or PET), the barrier layer (the middle layer of aluminum foil ) and inner layer (multifunctional high barrier layer).

Internal structure of the pouch cell aluminum-plastic composite film

Pouch lithium-ion batteries mainly include: aluminum-plastic film forming, top sealing and side sealing, liquid injection and pre-sealing, formation and shaping, exhaust and secondary sealing, trimming and folding.

However, due to the superimposed design inside the pouch battery, it is necessary to add a layer of thin sheets between every two batteries. Batteries require more complex battery control systems. At present, Audi e-tron, Mercedes-Benz EQC, Buick VELITE 6, Lynk & Co plug-in hybrid and other models use pouch batteries.

Buick VELITE 6 battery pack with pouch cells

Pouch cell with liquid cooling plate

Taking Buick VELITE 6 as an example, every two pouch batteries form the basis of a MINI stacking unit. Welded together by assembly line. The battery cells are separated by aluminum cooling fins, and the coolant is injected through the water injection port, filling the "capillary" on the cooling fins, circulating and taking away heat. In addition, the cooling liquid can also be heated through the coil to heat up the battery, ensuring that the battery is at the optimum operating temperature even in an extremely cold environment. Two pouch batteries, a "capillary" cooling sheet, plus a module frame and a piece of thermal insulation foam, constitute a complete "MINI stacking unit". A battery module assembly consists of 26 "MINI stacking units".

Summarize

With the continuous development of batteries, the penetration rate of pouch batteries in the new energy vehicle market will continue to increase. When the prismatic battery technology is gradually approaching the bottleneck period, pouch batteries with more mining potential and technical advantages will become substitutes. For consumers who are currently planning to buy new energy vehicles, battery quality is still an important consideration before buying a car. At this stage, various forms of batteries can be selected and there is no absolute advantage or disadvantage. Cylindrical battery technology The maturity and reliability are high, the square battery is in the middle position, and the pouch battery belongs to the most advanced of battery technology, but the requirements for the process are relatively high.

sales@quarelex.com

+63(0)954-229-7531(PH)

+1(626)715-3359(US)

+86-19899797548(CN)

Building 19, No. 89 Hezuo Road, Chengdu High-tech Zone, Sichuan, China, 610000