BLOG

If you are in solar business, you must have heard about a lot of inverter companies marketing there inverters as low frequency or high frequency inverter. What exactly do these two names mean?

1.First, what does the “frequency” mean?

The “frequency” in the low frequency inverter or high frequency inverter is not the AC output frequency. Because either low frequency inverter or high frequency inverter, the AC output frequency is the same as 50Hz or 60Hz.

The frequency refers to the DC-AC conversion mechanism within the inverter circuit.

2.What is the difference of DC-AC conversion between low frequency and high frequency inverter?

High Frequency Inverter

DC-AC conversion of a high frequency inverter typically goes through two steps:

First, high-frequency DC/DC conversion

The first stage of high-frequency inverter adopts high-frequency DC/DC conversion technology:

By inverting low-voltage direct current into high-frequency low-voltage alternating current.

Then the voltage is boosted by a high-frequency transformer.

After being rectified by a high-frequency rectification and filtering circuit, it becomes a high-voltage direct current usually above 300V.

Second, high voltage DC to AC

Finally, 220V low frequency AC power is obtained for the load through the low frequency inverter circuit.

Since the high-frequency inverter uses small-sized, light-weight high-frequency magnetic core materials, the power density of the circuit is greatly improved, so that the no-load loss of the inverter power supply is small, and the inverter efficiency is improved. Usually, the peak conversion efficiency of high-frequency inverters used in small and medium-sized PVS can reach more than 90%.

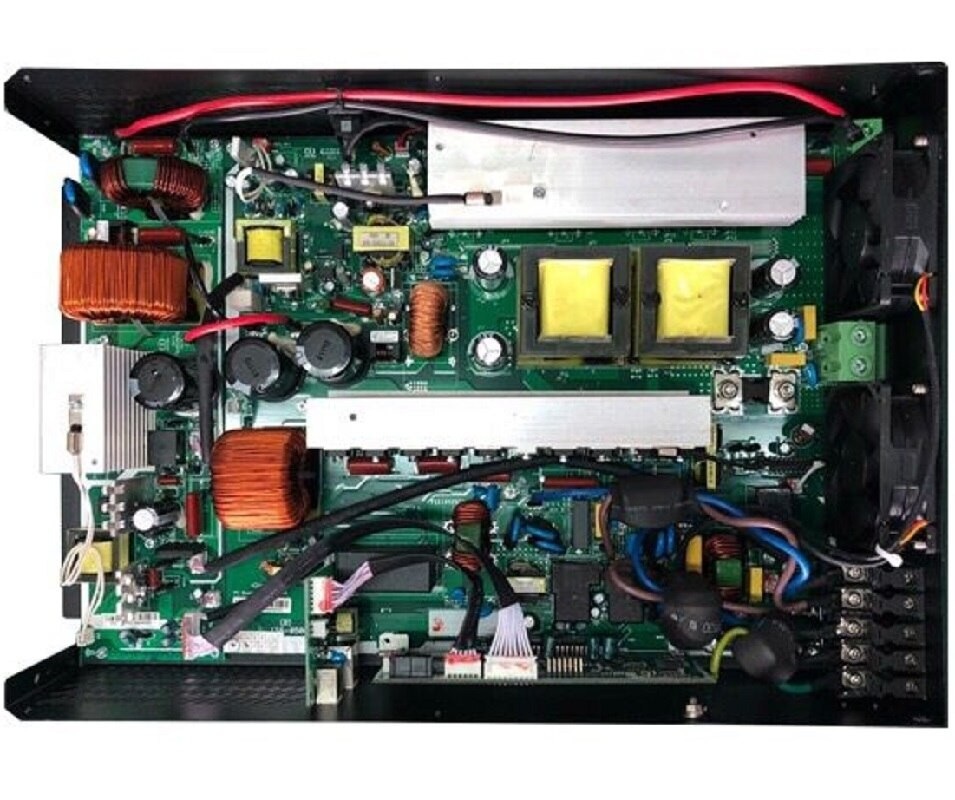

Picture 1. Typical high frequency inverter with small transformer

Low Frequency Inverter

The low frequency inverter first inverts the DC power into a low frequency low-voltage AC power, and then boosts it into 220V, 50Hz AC power for the load through a low frequency transformer.

Its advantage is that the structure is simple, and various protection functions can be realized at a lower voltage. Because there is a low frequency transformer between the inverter power supply and the load, the inverter runs stably and reliably, has strong overload capacity and impact resistance, and can suppress high-order harmonic components in the waveform.

However, low frequency transformers also have the problems of being bulky and expensive, and their efficiency is relatively low. The rated load efficiency of the small low frequency inverter manufactured according to the current level generally does not exceed 90%. At the same time, the iron loss of the low frequency transformer is basically unchanged when the low frequency transformer operates under full load and light load, so it can be operated under light load. The no-load loss is larger and the efficiency is lower.

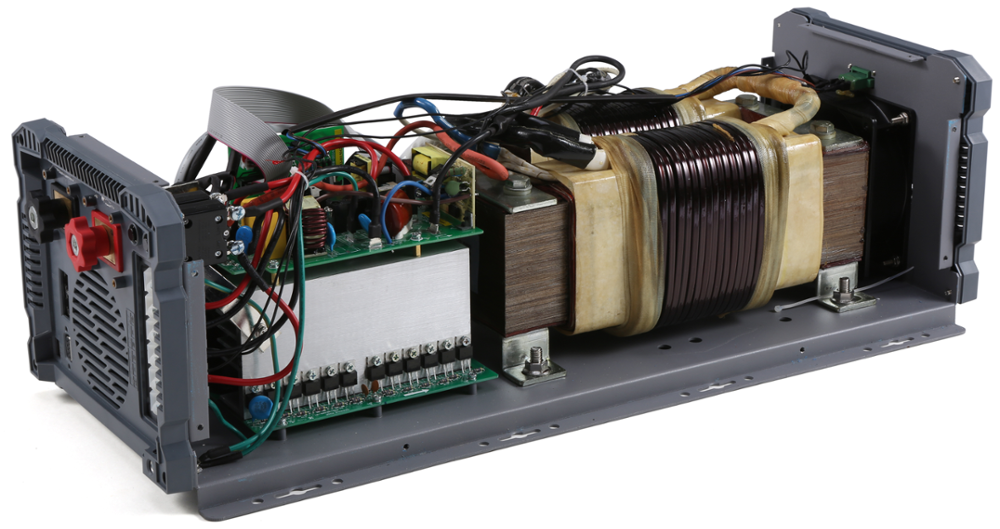

Picture 2. Typical low frequency inverter with heavy duty transformer

3. Comparison between low frequency and high frequency inverter

Weight

Low-frequency inverters are generally heavier than high-frequency inverters, mainly due to their larger and heavier transformers.

High frequency inverter can deliver the same power at higher frequency with a much smaller and lighter transformer, as a result, the high frequency inverter is lighter than low frequency inverters.

Efficiency

Low-frequency inverters are known for their robustness and ability to handle high surge currents, making them suitable for powering heavy-duty appliances or equipment with high starting currents, such as motors and compressors.

High-frequency inverters are generally more efficient than low-frequency inverters for maintaining a constant load for lighter loads. However, they may struggle with high surge currents or heavy loads.

Applications

Low frequency inverters are more suitable for off-grid systems where heavy loads and extreme conditions are expected, such as in industrial applications or in remote locations with harsh environments.

High frequency inverters are better suited for off-grid systems with lighter loads and more stable operating conditions, such as residential light-load household appliances or small-scale off-grid installations.

About quarelex

Established in 2017, Enerri Energy Group(parent company of quarelex), is one of the pioneering companies in applying the lithium-ion battery technology into low-speed motive power batteries and also battery energy storage systems(BESS). Our key solutions include:

1.Lithium-ion(LiFePO4) power batteries for material handling equipment: Forklifts, Narrow Aisle Trucks, Walkie Pallet Jacks, AGVs, etc.

2.Lithium-ion(LiFePO4) power batteries for low-speed vehicles: Golf Carts, E-Bikes, etc.

3.Lithium-ion(LiFePO4) storage batteries for hybrid/off-grid solar system: Residential low&high voltage battery, Commercial battery energy storage systems(BESS).

4.Solar inverters: hybrid, off-grid solar inverters for residential solar systems.

5.Lithium-ion battery charger: 24V-96V, 10A-300A.

6.Cloud-based Energy Management System(EMS).

sales@quarelex.com

+63(0)954-229-7531(PH)

+1(626)715-3359(US)

+86-19899797548(CN)

Building 19, No. 89 Hezuo Road, Chengdu High-tech Zone, Sichuan, China, 610000